I’m beginning to sound like a schill (no, not a typo, just a bad joke: short for [Curt] Schilling, the former Red Sox pitcher — sorry, I can’t get those guys out of my head today…) for GE, but it’s hard to argue with their impressive record of walking their talk about the “Industrial Internet,” their marketing term for the subset of the Internet of Things dealing with the industrial sector.

The latest evidence? A report today in the NYTimes‘ “Bits” blog that GE has just announced “14 more products that combine industrial equipment, Internet-linked sensors and software to monitor performance and analyze big streams of data. G.E. had previously announced 10 similar industrial products.”

Equally impressive, the Industrial Age behemoth turned nimble IoT leader said that by next year, almost all industrial products it makes will have built-in sensors and Big Data software to analyze the huge data streams those sensors will create.

Right now I’m writing an e-book on IoT strategy for C-level executives (not sure if I can disclose the customer — it’s a big one!) and GE VP of Global Software William Ruh, used the news to fire a shot across the bow at companies that are slow to realize a fundamental paradigm shift in manufacturing, product design and maintenance is well underway:

““Everyone wants prediction about performance, and better asset management… The ideas of speed, of information velocity, is what will differentiate the winners from the losers.”

You in the corner office: got your attention?

Equally important, given my insistence that the IoT is all about collaboration, GE simultaneously announced partnerships with Cisco, AT&T and Intel. It had already inked deals with Accenture and Amazon’s cloud subsidiary and has also invested in Pivotal, an Industrial Internet app creator.

Smart companies will follow GE’s lead in radically reforming the product design process to capitalize on the rapid feedback on performance that the Industrial Internet products’ built-in sensors yield. According to Ruh, they’re switching to an iterative design process, with rapid changes based on data from the field:

“… G.E. is adopting practices like releasing stripped-down products quickly, monitoring usage and rapidly changing designs depending on how things are used by customers. These approaches follow the ‘lean start-up’ style at many software-intensive Internet companies.

“’We’re getting these offerings done in three, six, nine months,’ he said. ‘It used to take three years.’” (my emphasis)

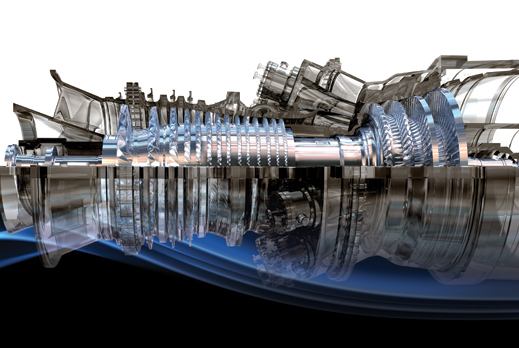

That change is definitely going to make it into my e-book! Brilliant example of how the IoT, by allowing companies to think in terms of systems dynamics, especially feedback loops, will have profound impacts on the design and manufacturing processes, integrating them as never before (oh, and don’t forget, the data from the built-in sensors will also allow companies to start marketing services — such as leasing jet turbines, with the lease cost based on the actual amount of thrust the engines create)!

Combined, that’s definitely a paradigm shift!

Oh, I almost forgot. Here’s a brief rundown of the products themselves and the industries served. They are clustered under the Predictivity name, and are powered by Predix, a new IoT platform:

- The Drilling iBox System (oil and gas)

- Reliability Max (oil and gas

- Field 360 (oil and gas)

- System 1 Evolution (oil and gas)

- Non-destructive Testing Remote collaboration (oil and gas)

- LifeMax Advantage (power and water)

- Rail Connect 360 Monitoring and Diagnostics (transportation)

- ShipperConnect (transportation)

- Flight Efficiency Services (aviation)

- Hot SimSuite (healthcare)

- Cloud Imaging (healthcare)

- Grid IQ Insight (energy management)

- Proficy MaxxMine (energy management)

Given the diversity of industries the Predictivity products serve and GE’s global clout, I predict this level of commitment will radically accelerate the IoT’s adoption by big business, as well as accelerating the payback in terms of lower operating, energy and maintenance costs, and reduced environmental impacts.

Will GE’s competitors in these sectors get on board, or will they be left in the dust?