Tragically, the Boeing 737-Max includes an Internet of Things technology — the “digital twin” — that might have avoided the current tragedies, if only its use had been extended from the engines to the entire plane’s operations. Even if your products don’t involve such high stakes as a jet plane does, your company should seriously consider adding the digital twin to your services, because it can benefit every aspect of your operations and strategy.

Let me explain.

A joint venture company between GE Aviation and a French company makes the Max’s CFM International LEAP engines. Every one of them is paired to a digital representation of the engine, a digital twin, that allows an engineer thousands of miles away to instantly monitor an inflight engine’s current operations. That, among many other benefits, allows GE to replace the preventive maintenance of the past, which had to rely on after-the-fact data about when the average engine needed to be maintained, with “predictive maintenance,” which uses data about the earliest evidence of a possible problem to trigger a sequence to intervene early on, well before a major problem. At its most extreme, that could mean that when a plane whose sensors have detected an engine anomaly lands at its destination, the mechanic would be ready to go, knowing not only where in the engine the problem existed, but also having had the replacement part automatically dispatched from a distribution hub, so the replacement could be done quickly and at least cost. No wonder GE has created more than hundreds of thousands of digital twins for products ranging from the jet engines to medical devices.

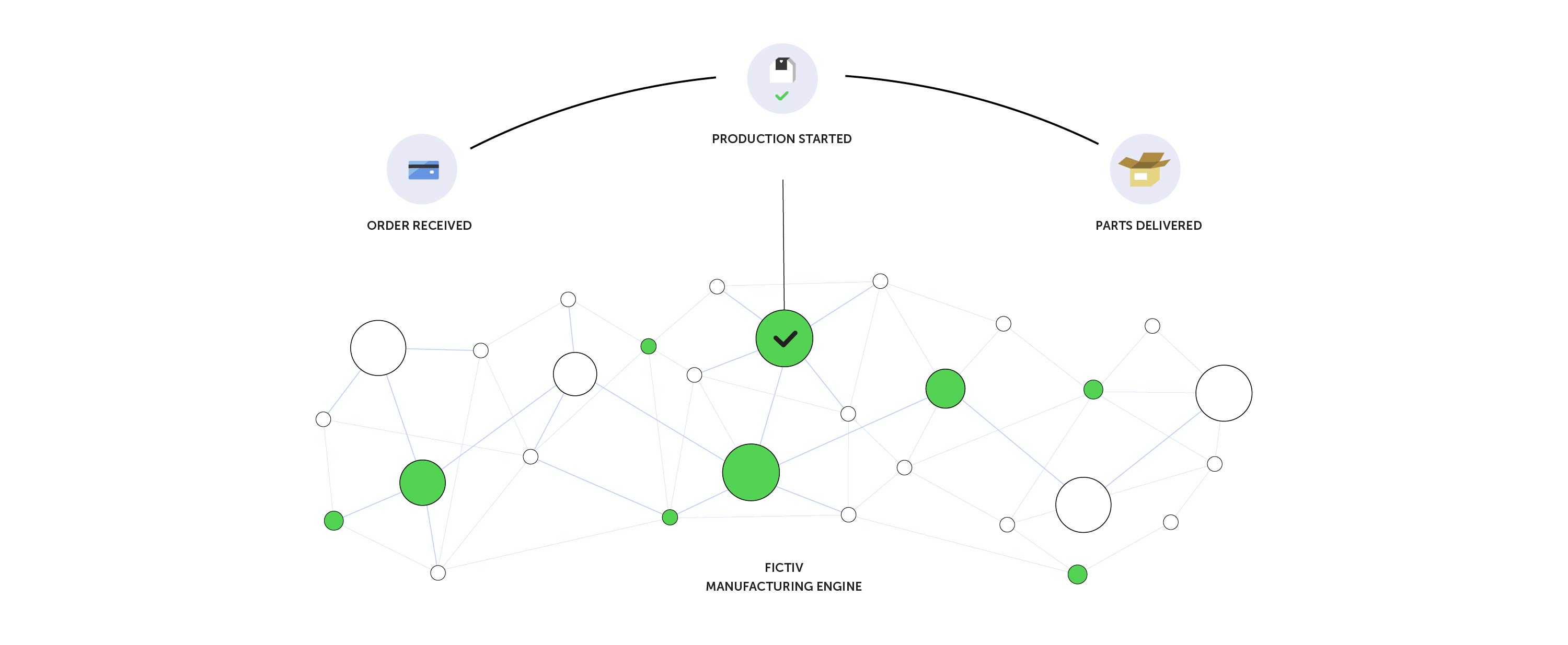

What if Boeing had extended the “digital twin” concept to the entire plane’s operations, including the navigation software? The real essence of the Internet of Things — of which the digital twin is perhaps the ideal example of how the IoT merges the digital and physical — is that it allows everyone who needs it to instantly share (the verb is critical!) that real-time data — something that was impossible in the past. In this case, that could mean real-time sharing between the cockpit, the airline, and Boeing, rather than after the fact harvesting of data from a plane’s “black box.” Hypothetically, the ability to share the real-time cockpit data would have meant that all those parties could have collaboratively brainstormed solutions to possible in-flight problems such as the maneuvering characteristics augmentation system, (MCAS) that has been fingered the possible cause of the problems.

OK, how does this ability to share real-time data from a digital twin apply to your company’s products and operations?

The potential benefits extend to every aspect of your operations:

- Maintenance, as with the jet engines, the twins can predict possible problems and intervene via predictive maintenance to minimize the cost and interruption from servicing.

- Operations: As I’ve written before, Siemens’ “Factory of the Future” enjoys a 99.9985% quality rate. One factor is a smart factory digital twin that is totally connected to its product lifecycle management software. Everything happening on the shop floor is recorded and pushed back to the PLM system. Extending the benefits, Siemens now requires its suppliers to provide digital twins of their parts.

- Design, to document patterns of problems either with parts or ease of use that can be used to design upgrades that will be more dependable and user-friendly. who conceived the digital twin, GM simulates their new engines’ operations instead of creating models. GE says it can push a new product out much more rapidly because instant feedback from products in use allows much more rapid refinements.

- Supply chain partners, to see if certain parts need to be replaced more frequently in one area than another (for example, jet turbine parts in areas with wind-blown sand).

- Marketing, to see if there are consistent patterns of product misuse that indicate the need to rewrite the manual, or to add new features (think of this in terms of pilots’ concern with the current problem).

More radically, the digital twin’s benefits in terms of reliability and improved design can allow a fundamental change in your business model, away from selling products to leasing them, with the customer’s actual cost based on use of the product (if the turbine is sitting on the ground being repaired, it ain’t bringing the manufacturer any revenue!). All three major jet turbine manufacturers — GE, Pratt & Whitney, and Rolls-Royce — have made this switch. They can even create new revenue streams by selling the real-time in-flight data to airlines, which can mash it up with atmospheric conditions, fuel prices, etc., to maximize flight efficiency. Similarly, Hortilux, which makes greenhouse lights, now provides artificial light, plus data on growing conditions, rather than selling the bulbs.

Even more important than the potential to improve individual aspects of operations through digital twins is the potential for innovation and creativity if all departments (and, if you choose, even supply chain and distribution network partners and, conceivably, your customers) look at and can discuss the data—ground truth—simultaneously.

Determination of exactly what happened and why with the 737-Maxes will require intense scrutiny, but your company can benefit from the wake-up call these tragedies have provided to the IoT’s new-found ability to gather and share operating data instantly, with the result being improving every aspect of your operations and strategy.

This is an issue that I first visited with my “

This is an issue that I first visited with my “