Pardon me, but I still take the increasingly-unfashionable view that we need strong, activist government, to protect the weak and foster the public interest.

That’s why I’m really passionate about the concept (for what it’s worth, I believe I’m the first to propose this approach) that we need Internet of Things enabled “real-time regulation” that wouldn’t rely on scaring companies into good behavior through the indirect means of threatening big fines for violations, but could actually minimize, or even avoid, incidents from ever happening, while simultaneously improving companies’ operating efficiency and reducing costly repairs. I wrote about the concept in today’s O’Reilly SOLID blog — and I’m going to crusade to make the concept a reality!

I first wrote about “real-time” regulation before I was really involved in the IoT: right after the BP Gulf blow-out, when I suggested that:

The .. approach would allow officials to monitor in real time every part of an oil rig’s safety system. Such surveillance could have revealed the faulty battery in the BP rig’s blowout preventer and other problems that contributed to the rig’s failure. A procedure could have been in place to allow regulators to automatically shut down the rig when it failed the pressure test rather than leaving that decision to BP.”

Since then I’ve modified my position about regulators’ necessarily having first-hand access to the real-time data, realizing that any company with half a brain would realize as soon as they saw data that there might be a problem developing (as opposed to having happened, which is what was too often the case in the past..) would take the initiative to shut down the operation ASAP to make a repair, saving itself the higher cost of dealing with a catastrophic failure.

As far as I’m concerned, “real-time regulation” is a win-win:

- by installing the sensors and monitoring them all the time (typically, only the exceptions to the norm would be reported, to reduce data processing and required attention to the data) the company would be able to optimize production and distribution all the time (see my piece on “precision manufacturing“).

- repair costs would be lower: “predictive maintenance” based on real-time information on equipment’s status is cheaper than emergency repairs.

- the public interest would be protected, because many situations that have resulted in disasters in the past would instead be avoided, or at least minimized.

- the cost of regulation would be reduced while its effectiveness would be increased: at present, we must rely on insufficient numbers of inspectors who make infrequent visits: catching a violation is largely a matter of luck. Instead, the inspectors could monitor the real-time data and intervene instantly– hopefully in time to avoid an incident.

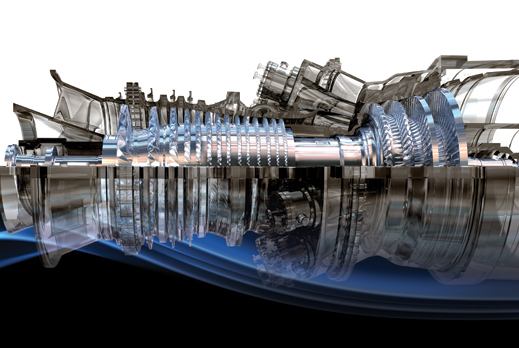

Even though the IoT is not fully realized (Cisco says only 4% of “things” are linked at present), that’s not the case with the kind of high-stakes operation we’re most concerned with. GE now builds about 60 sensors into every jet, realizing new revenues by proving the real-time data to customers, while being able to improve design and maintenance by knowing exactly what’s happening right now to the engines. Union Pacific has cut dangerous and costly derailments due to bearing failures by 75% by placing sensors along the trackbed.

As I said in the SOLID post, it’s time that government begin exploring the “real-time regulation” alternative. I’m contacting the tech-savvy Mass. delegation, esp. Senators Markey and Warren, and will report back on my progress toward making it a reality!