There are so many direct, quantifiable benefits of the IoT, such as increased quality (that 99.9988% quality rate at Siemens’s Amberg plant!) and precision, that we may forget there are also potential intangible benefits.

Most important of those is customer loyalty, brought about by dramatic shifts both in product designs and how they are marketed.

Much of this results from the IoT lifting the veil of Collective Blindness to which I’ve referred before: in particular, our prior inability to document how products were actually used once they left the loading dock. As I’ve speculated, that probably meant that manufacturers got deceptive information about how customers actually used products and their degree of satisfaction. The difficulty of getting feedback logically meant that those who most liked and most hated a product were over-represented: those who kinda liked it weren’t sufficiently motivated to take the extra steps to be heard.

Now, by contrast, product designers, marketers, and maintenance staffs can share (that critical verb from my Circular Company vision!) real-time data about how a product is actually operating in the field, often from a “digital twin” they can access right at their desks.

Why’s that important?

It can give them easy insights (especially if those different departments do access and discuss the data at the same time, each offering its own unique perspectives, on issues that will build customer loyalty:

- what new features can we add that will keep them happy?

- can we offer upgrades such as new operating software (such as the Tesla software that was automatically installed in every single car and avoided a recall) that will provide better customer experiences and keep the product fresh?

- what possible maintenance problems can we spot in their earliest stages, so we can put “predictive maintenance” services into play at minimal cost and bother to the customer?

I got interested in this issue of product design and customer loyalty while consulting for IBM in the 9o’s, when it introduced the IBM PS 2E (for Energy & Environmental), a CES best-of-show winner in part because of its snap-together modular design. While today’s thin-profile-at-all-costs PC and laptop designs have made user-friendly upgrades a distant memory, one of the things that appealed to me about this design was the realization that if you could keep users satisfied that they were on top of new developments by incremental substitution of new modules, they’d be more loyal and less likely to explore other providers.

In the same vein, as GE has found, the rapid feedback can dramatically speed upgrades and new features. That’s important for loyalty: if you maintain a continuing interaction with the customer and anticipate their demands for new features, they’ll have less reason to go on the open market and evaluate all of your competitors’ products when they do want to move up.

Equally important for customer loyalty is the new marketing options that the continuous flow of real-time operating data offer you. For a growing number of companies, that means they’re no longer selling products, but leasing them, with the price based on actual customer usage: if it ain’t bein’ used, it ain’t costing them anything and it ain’t bringing you any revenue!

Examples include:

- jet turbines which, because of the real-time data flow, can be marketed on the basis of thrust generated: if it’s sitting on the ground, the leasee doesn’t pay. The same real-time data flow allows the manufacturer to schedule predictive maintenance at the earliest sign of a problem, reducing both its cost and the impact on the customer.

- Siemens’s Mobility Services, which add in features such as 3-D manufactured spare parts that speed maintenance and reduced costs, keeping the trains running.

- Philips’s lighting services, which are billed on the basis of use, not sold.

- SAP’s prototype smart vending machine, which (if you opt in) may offer you a special discount based on your past purchasing habits.

At its most extreme is Caterpillar’s Reman process, where the company takes back and remanufactures old products, giving them a new life — and creating new revenues — when competitors’ products are in the landfill.

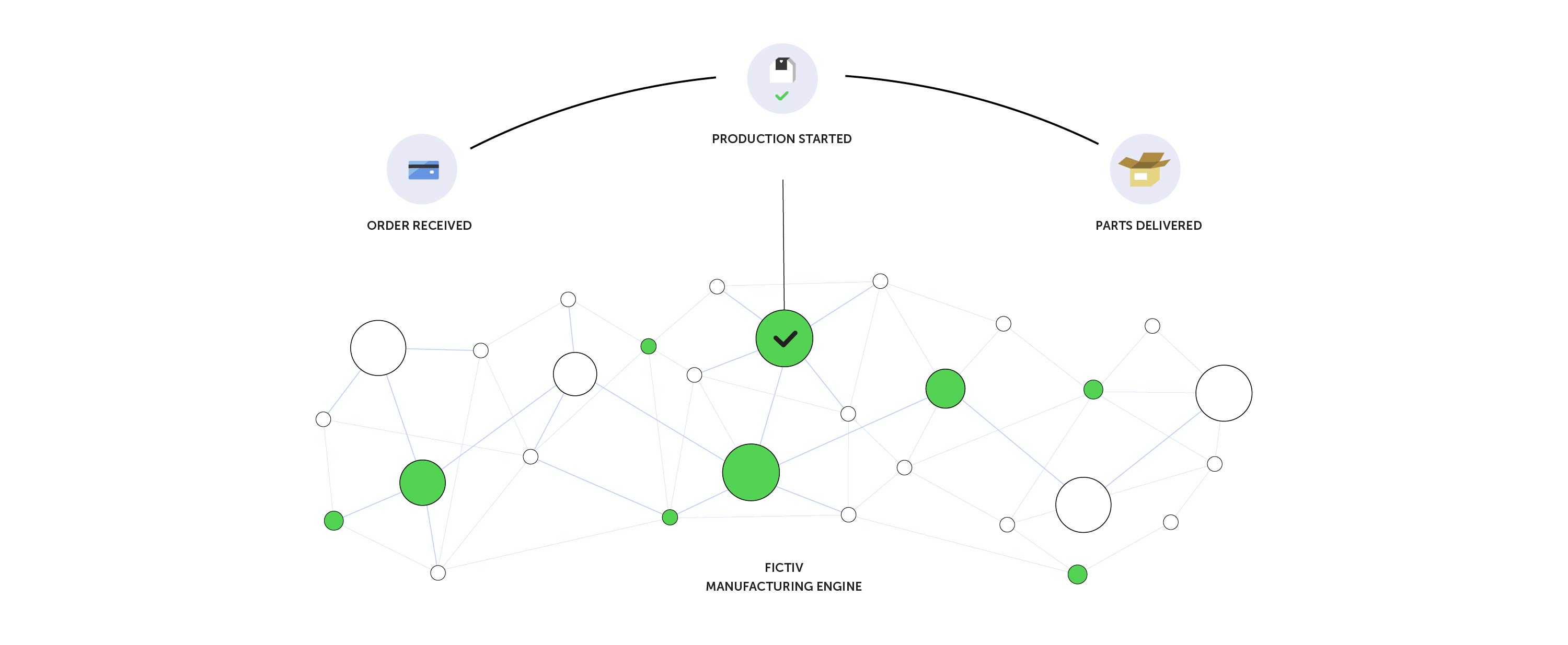

Loyalty can also be a benefit of IoT strategies for manufacturers’ own operations as well. Remember that the technological obstacles to instant sharing of real-time data have been eliminted for the supply chain as well. If you choose to share it, your resupply programs can also be automatically triggered on a M2M basis, giving an inherent advantage to the domestic supplier who can get the needed part there in a few hours, versua the low-cost supplier abroad who may take weeks to reach your loading dock.

It may be harder to quantify than quality improvements or streamlined production through the IoT, but that doesn’t mean that dependable revenue streams from loyal customers aren’t an important potential benefit as well.